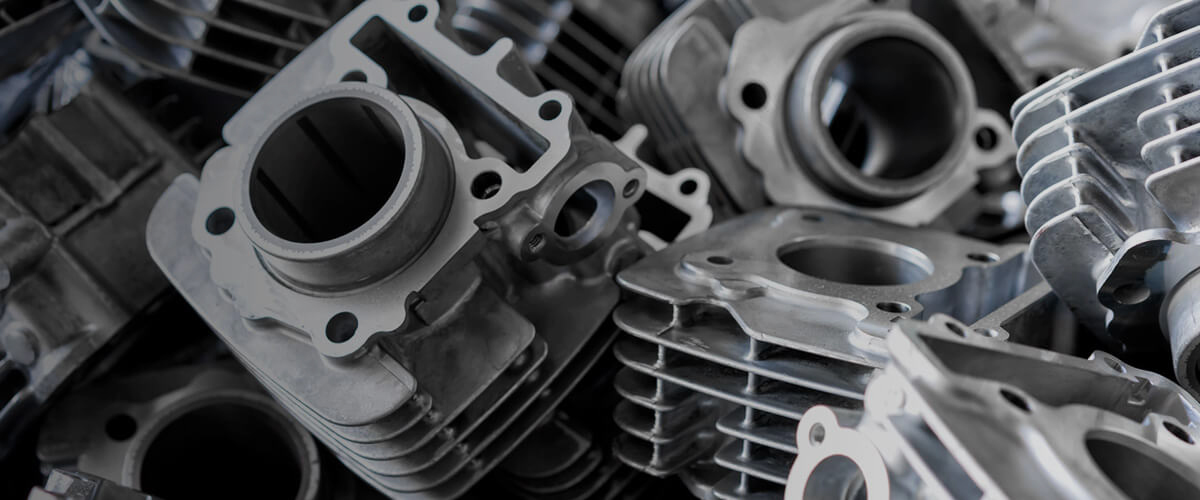

Die casting manufactures medical parts and components that are precision-machined with very tight tolerances, high-strength and durable metal parts that are ideal for medical devices. At Rex, through our 10 years of die casting experience, we bring our customers the precision, well-made die casting products, including the advantages of medical device die casting:

- Advanced manufacturing technology, higher strength and dimensional stability.

- Sophisticated design capabilities to produce complex geometry with tight tolerances.

- Large batch production, reduced assembly, and cost effective.

- Excellent surface finish, uniformity of die castings.

What are the medical die casting products?

Medical die casting products include:

- Medical equipment castings, diagnostic equipment, ultrasound equipment

- Medical cosmetic equipment base castings, medical cosmetic instruments, medical instrument aluminum castings.

- Medical monitors, X-ray machines, electric hospital beds, portable oxygen pumps, and many other high-tech medical devices

What are the surface treatment processes available for medical die casting?

- Vibrational deburring

- Shot blasting

- Polishing

- Electroplating

- Other

For specific medical casting products that use different surface treatments, you can send your drawings to our professional engineers and contact us to help make the perfect product.

What alloys are commonly used in medical die castings?

The most commonly used alloys for medical castings are aluminum, aluminum-silicon, and aluminum-silicon copper alloys. Aluminum provides the flexibility and durability needed for medical parts when strength and lightweight versatility are critical. Aluminum has a high melting temperature and can be die-cast. It is also an ideal metal choice for high-volume handling of parts.

As an ISO 9001 certified die casting manufacturer with 10 years of experience, our professional die casting experts will be there for you all the way, whether you have any questions, need quotation or technical support. With one-stop service of excellent mold design and production, die casting production, precision machining, surface treatment, Rex will help you get a batch of high-quality medical die casting and occupy a larger market.