SERVICES

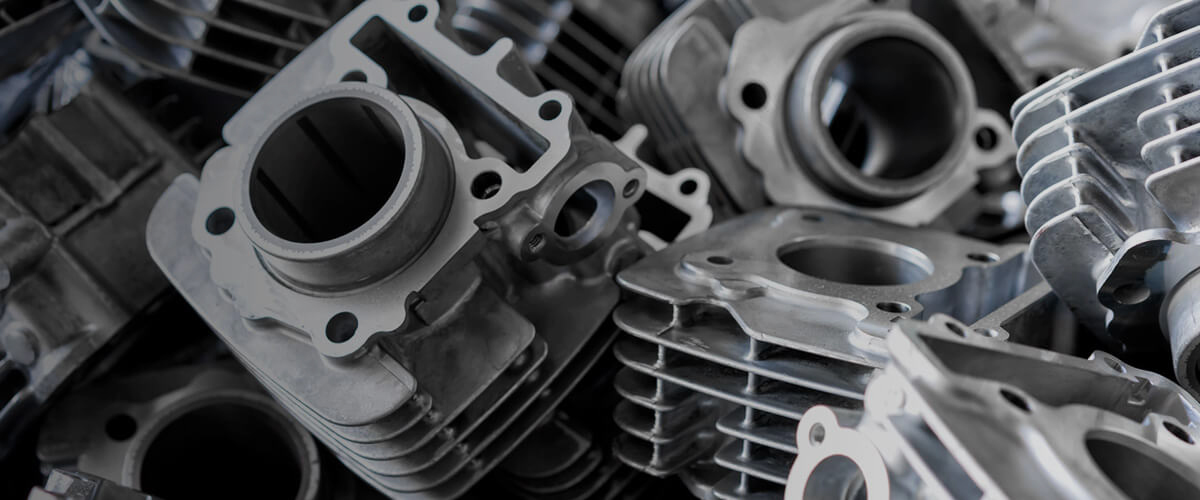

Gravity casting, also called gravity die casting, is a modern process of making molds from heat-resistant alloy steel. The liquid or molten metal is poured into a pernanent mold or steel die and filled the cavity with gravity rather than high pressure. The main process of gravity casting is, melting, casting mold filling, exhaust, cooling, mold opening, heat treatment and pose processing. Rex mainly provides the products such as high precision automobile and motorcycle machinery parts, power tool parts, stainless steel marine hardware, stainless steel pipe and valve parts, stainless steel building hardware components, power fittings, high conductive pure copper parts and various copper alloy precision castings.The parts are exported to the United States, France, Germany, Japan, Australia, South Korea, the United Kingdom, Italy and other countries.

Gravity Casting

Advantages of gravity casting:

1,The parts of gravity casting with less pores and can be heat treated. After heat treatment, the strength of the products can be greatly improved, even more than the die casting products.

2, The cost of gravity mold is lower than the cost of other processes.

3, Highly repeatable and simple process, suitable for mass operation.

4, Large range of alloy choices.The special aluminum alloy with low liquidity can be manufactured by gravity casting way.

Disadvantages of gravity casting:

1,The surface of the product is not smooth enough, the gravity casting products tend to form pits on the surface after cooling similar to those that are easily generated after shot blasting.

2,Slow filling speed and low production efficiency. Its production efficiency is only 1/4 of the high pressure die casting, leading to the increase of production cost.

3, Simple process isn’t suitable for the production of thin-walled parts.

4, Low product density. Depending on the liquid self-weight molding, the product density and the its strength are lower than that of die casting, but its elongation is higher.

+86-592-6080720

contactus@xmrex-tech.com

Skype:duchy.evelyn

Our Products

Our Products

Our Services